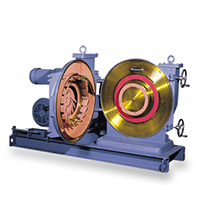

The Micro Cut air classification machine precisely and efficiently separates particles into large particles and small particles. It does this by using the interaction of the centrifugal force applied to the particles by the swirling airflow and the adhesion force of air caused by the airflow's axis of rotation.

There are two types of Micro Cut available: The horizontal model for classification of micro-powders and the vertical model, which requires no external collector.

Features

- Horizontal

- Classification point as small as 2 to 3μm.

- Low power consumption and high per-unit processing power.

- Classification efficiency is performed with a small ratio of air to the materials.

- Vertical

- The collection mechanism for micro-powders is built in, and so no collection equipment is required.

- The shaft of the classification chamber is vertical, and so little floor space is required.

Applications

Calcium carbonate, quicklime, slaked lime, ceramic materials, starch, flour, powdered paint, talc, kaolin, glass cullet, metallic powders, aluminum dust, health foods, etc.

Standard Specifications

Horizontal

Vertical

| Model | Classification diameter (μm) |

Processing volume (kg/h) | Equipment power (kW) |

| YACA- 132H |

2.5〜15 | 〜100 | 2.2 |

| YACA- 400H |

6〜50 | 〜2500 | 5.5〜30 |

| YACA- 400HS |

3.5〜50 | 〜1500 | 7.5〜30 |

| ※YACA- 400HU |

5〜30 | 150〜300 | 22 |

※ Note: The 400HU was developed for toners.

| Model | Classification diameter (μm) |

Processing volume (kg/h) | Equipment power (kW) |

| YACA- 400V |

8〜100 | 0.3〜2 | 2.2〜7.5 |

| YACA- 600VB |

10〜100 | 1〜5 | 11〜30 |

| YACA- 1000V |

15〜100 | 2〜10 | 22〜45 |

| YACA- 1350VB |

20〜100 | 4〜20 | 55〜110 |