The contact frequency with the screen is high because the material is uniformly dispersed on the screen surface and complete mixing is performed vertically.

This basic vibration screen effectively uses 100% of the screen while transporting the particles.

Features

- You can select the screen with the best oscillation, vibration frequency, and vibration angle to suit the characteristics of the powder in applications using a vibrating feeder or conveyor.

* Movement in a straight line is produced by operating two Uras Vibrators in opposite directions from each other. This movement is used to screen the material.

- A wide assortment of models is available for different applications.

EEnclosed models (with cover) and open models (no cover) are available.

EModels are available with a variety of installation positions for the Uras Vibrator: Bottom,side,or top.

Bottom installationSide installationTop installation

Bottom installationSide installationTop installation - Variety of Screens to Match the Powder Characteristics

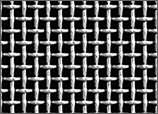

Metal screen

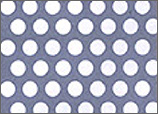

Punching

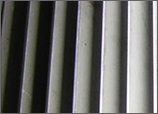

Louvers

Comb teeth

Wedged wire

Urethane screen

Applications

EScreening of mineral products,chemical products, resins, foods, pharmaceutical products, and other powders

EDehydration for a variety of materials

EDehydration for a variety of materials

Standard Specifications

| Screen opening | Effective screen area | Applicable Uras Vibrators | Number of decks |

| 0.1`30mm | 0.31 to 9.4m² per deck | 0.13kW~2`3.7kW~2 4`8P |

"1, 2, or 3decks can be used. |